Products

- Medical Dressings and Bandaging Products

- Medical Waste Disposal Products

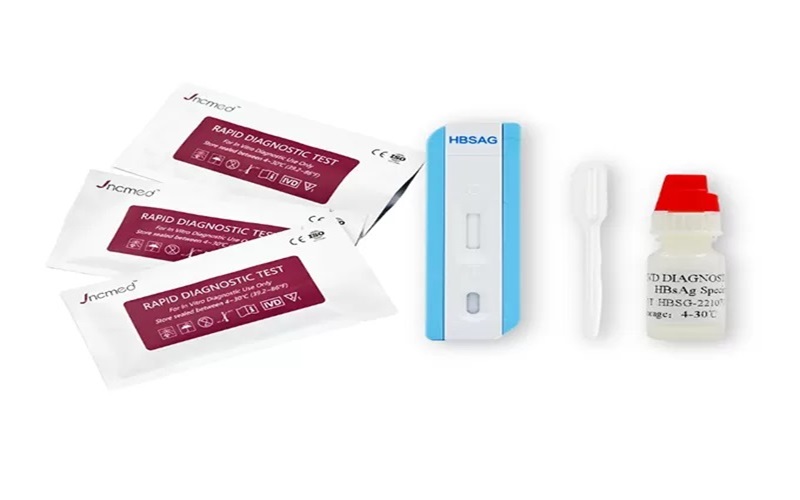

- In Vitro Diagnostic Reagents

- Respiratory Products

- Urology Products

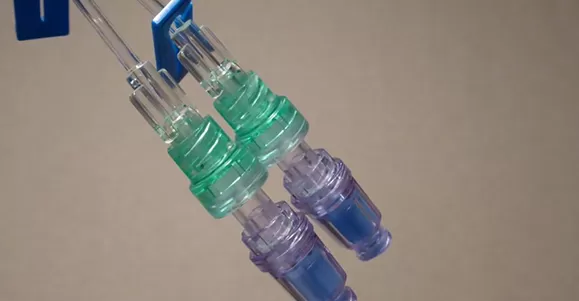

- Infusion Products

- Operating Room Infection Control Products

- Commercial Medical Consumables

- Anesthesia Products

- First Aid Products

- Personal Care Products

- Rehabilitation Products

- Home Medical Equipment

- Animal Test Kits

- Animal Infusion Products

- Animal Diagnostic Equipment

- Animal Medical Consumables

What are you looking for?